Coffee Roasting Process

The Maillard Reaction

Coffee is roasted between 180 ° C and 250 ° C. While inducing such temperatures the „Maillard-Reaktion“,occurs which affects the flavor, texture and smell. To date, not all the reaction products of these "Maillard reaction" identified. The green coffee beans are supplied to the roaster in jute bags or containers, depending on the size of the roaster (Small to industrial roaster). The beans are cleaned once more by sieving, removing the remaining residues and then transported to the roasting machine.

The Roasters

Essentially one can differentiate between two roasting machines:

- Drum Roaster

- Hot Air (Fluid Bed) Roaster

Drum Roaster

Drum roasters are mainly used by small to medium-sized coffee roasters plants and can roast between 5 kg to 120 kg per batch. Roast Masters, who want to achieve the highest quality work with drum roasters which offer a slower, more gentle roasting process.

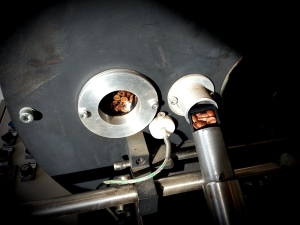

Kontrollschauffel

bei Trommelröster

The principle is independent of the size of the drum: horizontal rotating drums are externally heated and the all raw beans are evenly moved inside. The beans themselves never come into direct contact with the flame. A shovel is attached at the front of the roaster to control of the roasting process. The shovel allows taking samples of beans during the roasting process. Thus the roast master can continously monitor the color and sensorik elements of his roast. When the beans have reached the desired degree of roasting, they have to be cooled.

This is done by opening a flap on the roaster through which the beans fall on to a cooling sieve and will be cooled there by air suction and agitation. Finally, the beans still have to de-gas for some time until they can be packed.

Hot Air (Fluid Bed) Roaster

Hot Air (Fluid Bed) Roasters are primarily used by industrial coffee roasters. Emphasis is placed on maximum throughput and the highest possible automation. In contrast to drum roasting, the roasting time is reduced here to up to 90 seconds, the beans are heated by means of hot air flowing through perforated grids and are whirled through the air stream.Some variations are possible by transporting the beans on a conveyor belt. Some industrial roasters cool the beans with water, which may further contribute to loss of quality. Using such a "fast track" roasting method, flavors (as in the time-intensive drum roasting) and this leads to coffees with intense acidic taste.